Before the COVID-19 pandemic, air travel in Australia was big business.

The country’s four largest airports reported record profits in 2018-19. There were 42.5 million international passenger movements last calendar year, and 63.52 million domestic movements in the year to June 30, according to government numbers.

And all parts of the aviation industry were benefiting from the Internet of Things (IoT) and associated technology. It was being trialled or used to better manage aircraft movements, to optimise flight routes and aircraft maintenance, and to help ground crews that interact with the aircraft stay safe.

The complexity of that work will grow if the number of conventional flights operating in Australian airspace eventually returns to previous levels and increases. Prior to the pandemic, that number was expected to double over the next 20 years.

Add to that the anticipated rise of unmanned aerial vehicles, environmental challenges such as emissions and weather pattern predictability, and expectations from airlines and regulators, and the job of managing Australia’s skies becomes even more complex than it already has been.

Today, that job falls heavily on highly trained professional controllers from Airservices Australia, the government-owned corporation that provides air traffic control, aviation rescue and fire-fighting and air navigation services.

But, in the future, digital twin technology could shoulder some of their workload, while also helping them to model different strategies and scenarios aimed at solving emerging aviation challenges.

Complex simulations at scale

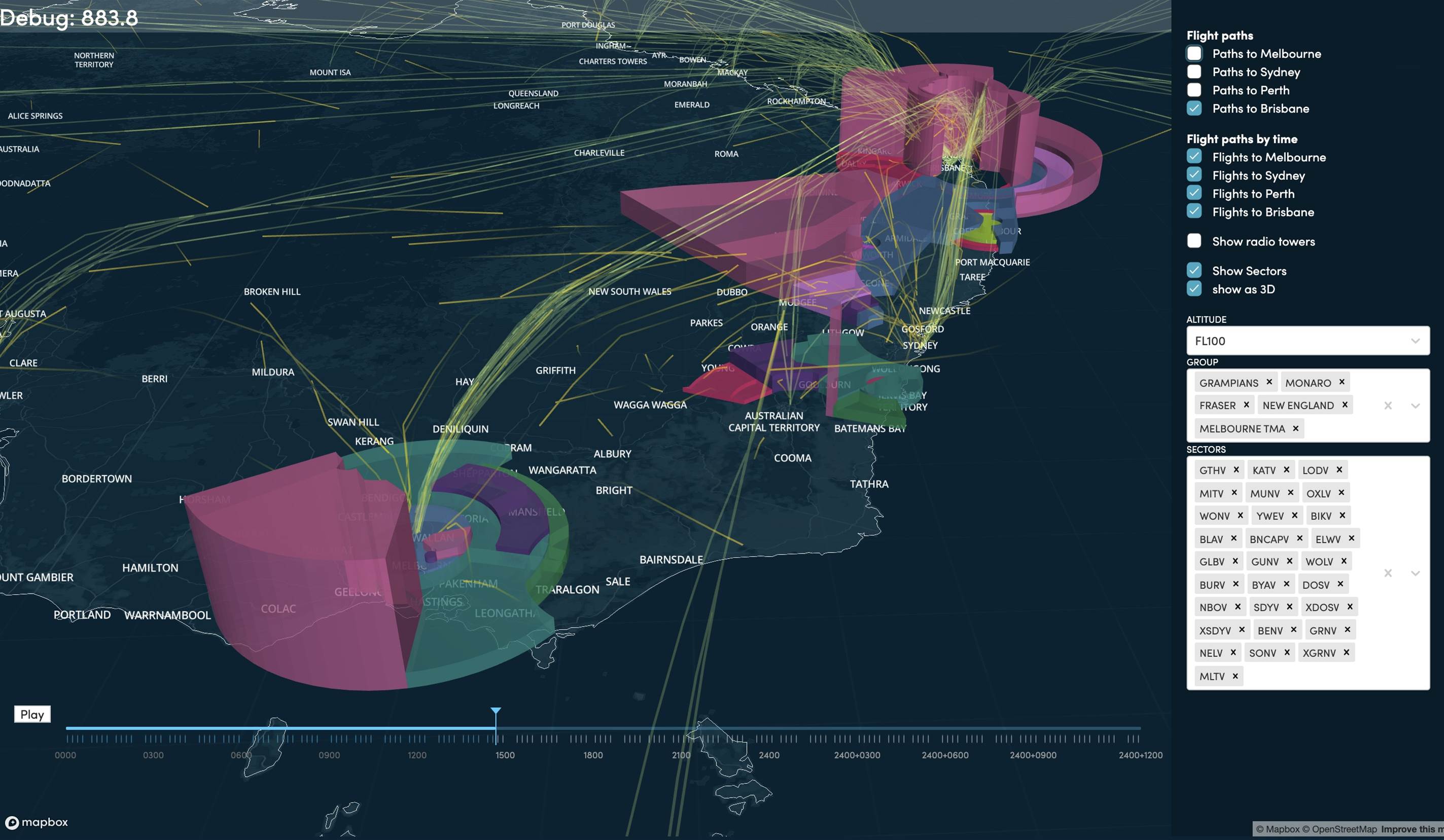

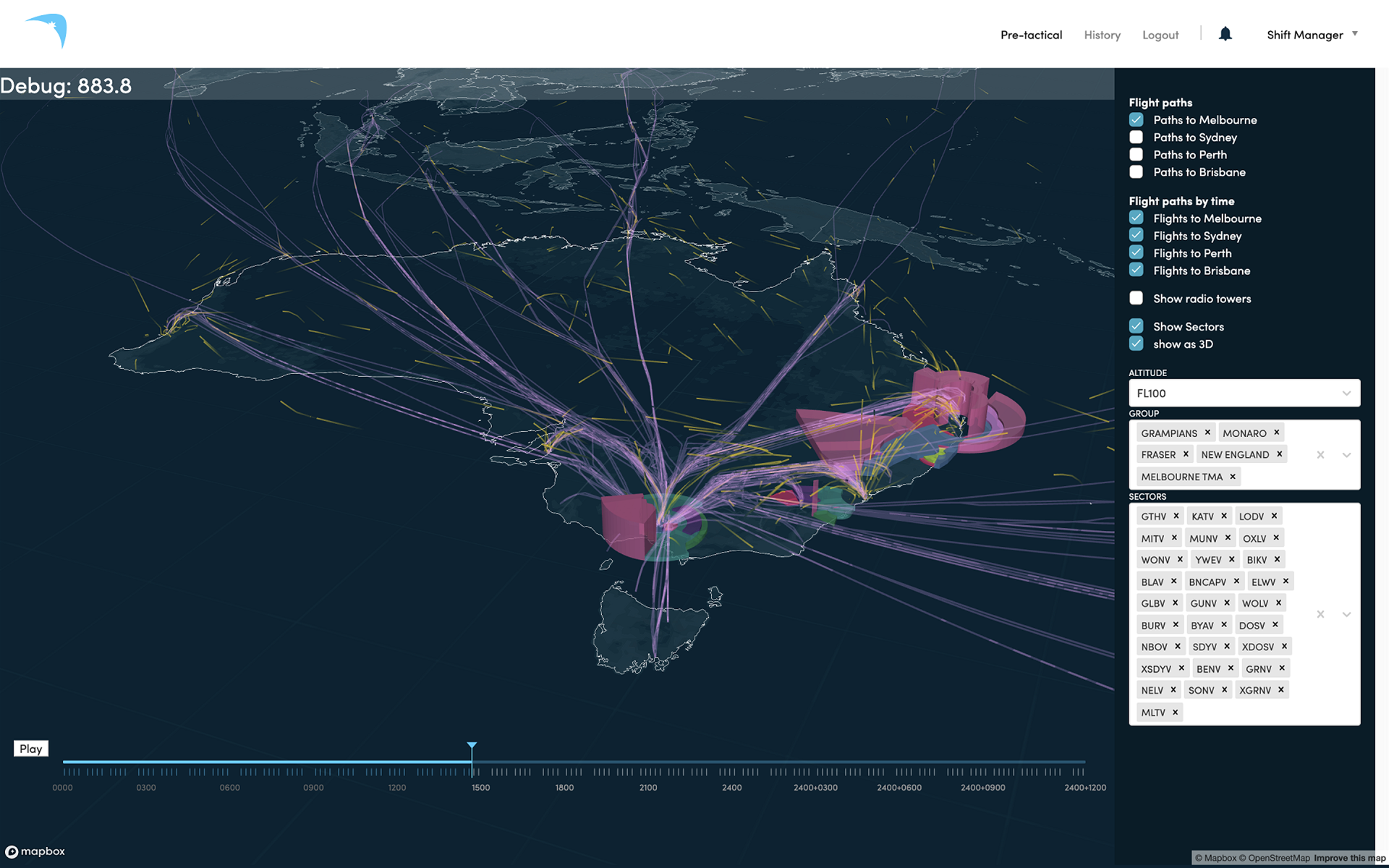

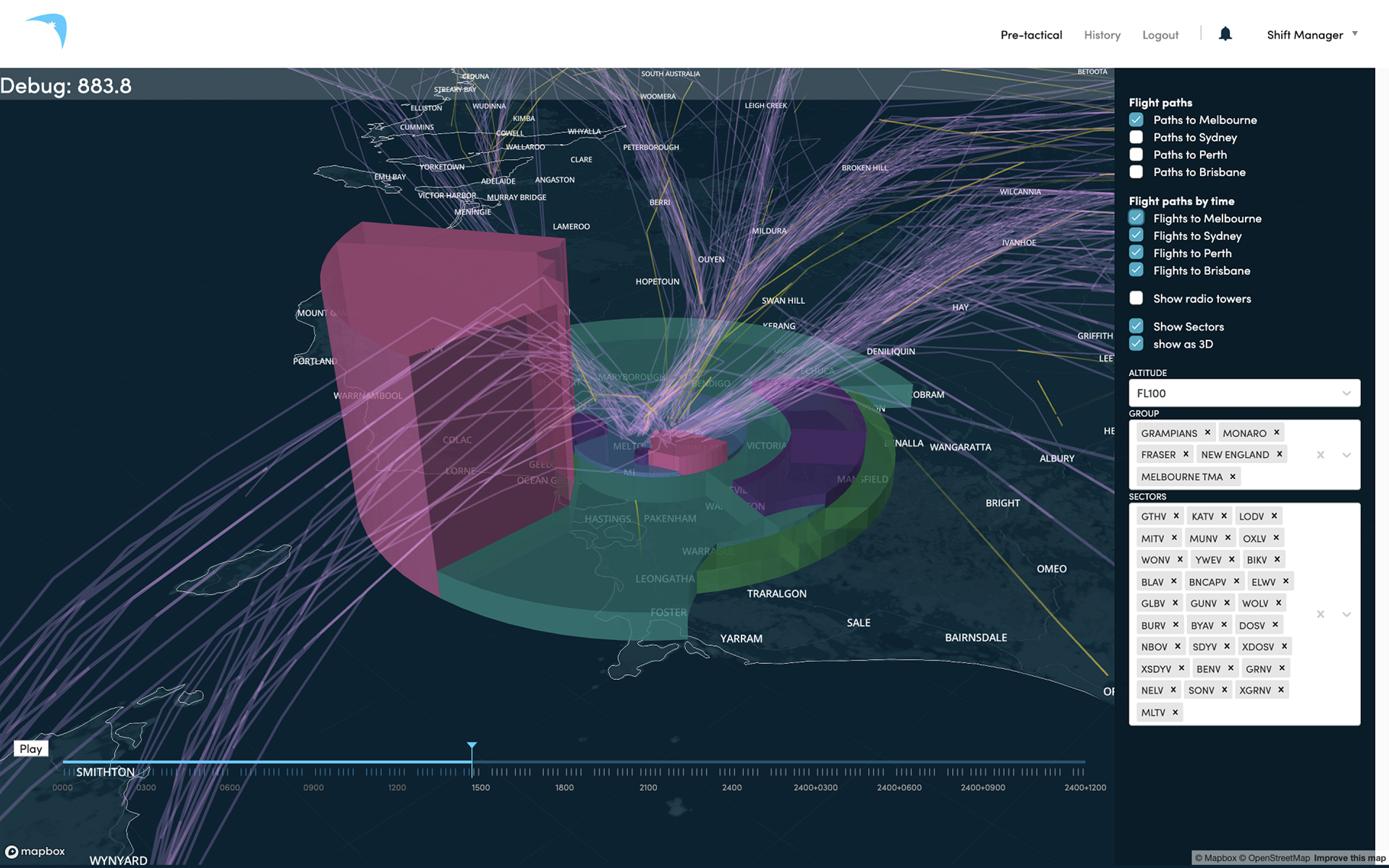

Airservices began work on a digital twin in 2019. It is a digital replica of Australian airspace, the aircraft in it and weather conditions affecting its use.

The digital twin leverages Deloitte’s digital twin framework. Underpinning that framework is a cloud-based modelling platform, to support the effective management of complex simulations at scale. Airservices has leveraged McLaren’s expertise in this domain, using techniques that allow “what if” scenarios at F1 speeds and with F1 accuracy. In addition to providing compute power, cloud also offers resilience and security, which is important given the critical nature of Airservices’ work.

So far, four proof-of-concepts have been run.

- The first sought to simulate and predict potential flight delays a day in advance, meaning informed decisions can be taken ahead of time by airlines and air traffic controllers.

- Two further proofs focused on helping controllers manage workloads, using the digital twin to predict how busy different flight sectors will be and to divide the workload more evenly among controllers.

- A fourth proof looked at the creation of a collaborative decision-making portal to share the results of simulations and decisions with industry.

Airservices’ early work took a ‘test and learn’ approach. The proofs demonstrated value and allowed the organisation to secure funding to move into the next phase: pre-production.

“The next phase, as we move into pre-production, will give us answers to key questions around predictive accuracy, processing speeds and data volumes,” says service strategy manager Michael Snell.

The proofs all used historical data sets. As Airservices moves into a pre-production phase, it will begin incorporating feeds of real-time data.

“A key design principle of the digital twin is to allow us to solve problems ‘in real time’,” says Snell. “We are focused on using this solution to support our air traffic network operations”

Airservices will use instrumented systems and IoT to capture and understand real world behaviours. It will soon have live weather from weather stations, airport data and more, all aiding real-time decision making.

It’s also anticipating dynamic and static data integration challenges, including bringing in real-time streaming of aircraft updates, live weather forecasts and real-time operational adjustments made by airlines.

Once the digital twin has been validated with real-time data, a full business case outlining metrics for success and benefits will be stood up. This is due in mid-2020.

“We believe what we have developed is unique in the market at the moment, a non-proprietary real time digital twin capable of optimising decisions for an ecosystem of assets,” says Snell.

“Very early results suggest that our digital twin could help us reduce the impact of airborne delays by as much as 20 to 30 percent”.

Heavy lifting

Swissport provides ground services and cargo handling for a range of major domestic and international carriers at 32 airports in Australia and New Zealand.

In May last year, it began trialling SoterSpine wearable technology by Perth-based startup Soter Analytics. The technology alerts workers if they make high-risk movements that could lead to injury.

Under the trial, employees are offered a small (30mm x 50mm x 10mm) lightweight SoterSpine device to clip to their collar to measure body movements and force. In addition to receiving real-time alerts, wearers are given access to a “3-5-minute personalised improvement program with a virtual coach delivered by mobile app” at the end of their shift.

A Swissport spokesperson told IoTHub.com.au that the trial started at Melbourne Airport, and has since been expanded to teams at Brisbane and Hobart airports.

“Around 100 staff from our ramp operations, customer service and cargo teams have been involved to date,” the spokesperson said.

It’s a 12-day program for each team member. Of the workers who have completed the trial, we have seen an overall reduction in awkward movements and postures of around 38 percent.

We also observed a general improvement in movement and posture awareness among staff who have not participated in the trial.

The next phase of its trial will focus on establishing a baseline of where the increased awareness remains effective, “so that programs can be developed to reignite the focus and positive behaviours when ‘old habits’ begin to creep back.”

Predictive maintenance for trains

Of course, air is but one of four major transport vectors in Australia, with rail being another major vector.

When it comes to rail transport, Downer Group is an IoT leader, using sensors on rolling stock for a real-time view of how trains are performing and to proactively predict when they might need maintenance work.

Its system, called TrainDNA, was initially developed on the Waratah fleet of passenger trains in Sydney.

Since then, TrainDNA has been rolled out on the Sydney Growth Trains project and is under development for the upcoming High Capacity Metro Trains project in Melbourne, Louisa De Vries, asset innovation manager for rollingstock services at Downer Group, tells IoThub.com.au.

When the project was first revealed, it was said that each train would use 300 sensors and 90 cameras to collect 30,000 data points every 10 minutes.

But De Vries says that during the development of TrainDNA, “it was quickly recognised that the quality of data is far more important than the quantity.”

“While 30,000 data points are collected every 10 minutes, only a subset of these are providing valuable information to infer the condition of components and subsystems on trains,” she says.

“Further research is being done on the remaining signals to determine if they can be used to get additional value.

“We have also identified some critical components that we could monitor by adding sensors, such as axle bearings using vibration sensors.”

The insights collected by TrainDNA also vary between train fleets, depending on what data is available and when.

“For example, the Millennium fleet in Sydney is 10 years older than Waratah and has far less sensors fitted, whereas the High Capacity Metro Trains in Melbourne has a similar number of data points transmitted at a once-a-minute frequency,” De Vries explains.

“This higher frequency of data transmission can capture data during events such as doors opening and closing, which would be missed at lower frequency, but does increase the total amount of data collected, stored, and analysed significantly.”

The impact of TrainDNA continues to expand as the platform develops.

So far, it is helping Downer Group to streamline maintenance by having a better understanding of asset condition. It also increases train availability and reliability, and improves safety due to the automation of high-risk tasks.

TrainDNA also enabled the launch of Downer’s Integrated Operations Centre (IOC), which co-located critical functions such as planning, engineering, mobile response and materials supply personnel. The IOC uses TrainDNA as well as other systems to provide real-time information to enhance fleet management and improve reliability, availability and response times.

Significant work was required to get to this point, particularly when it came to standing up a data analytics platform that could run at the required scale.

“While there is a vast amount of data available, it is not necessarily the right data, at the right frequency, or accessible for ingestion and analysis,” says De Vries.

Months were spent on data ingestion, validation, storage and algorithm development before any real insights could be gleaned on asset condition.

This was made easier by building TrainDNA within Neuroverse, a Downer in-house, cloud-based data analytics, visualisation and machine learning platform.

“But otherwise, we really have charted our own course in creating TrainDNA by building business rules one by one to sit behind the reports that you see in the platform. At this point in time, two years into the project, we are starting to see significant benefits.”

Still, according to De Vries, there is more to do.

“We are still in the process of building TrainDNA for all critical subsystems and components across the fleet,” De Vries says.

“The current focus is the bogie subsystem, where we are building algorithms using machine learning to combine acoustic and thermal data from wayside equipment with digital data from the train to glean insights into component condition.

“This could help identify component degradation months in advance, and ultimately lead to better reliability and availability across the fleet.”

De Vries also notes challenges with complex prediction models Downer has built “to alert failures for key components days in advance”.

“The models were built using eight years of historical data, but must be validated using live data prior to release, which can be challenging if data points drift as the fleet ages,” she explains.

"The prediction models we are building are not simple linear regression models, but rather complex algorithms developed over many months using seemingly unrelated data sets to draw insights from.

Validating these prediction models is a vital step in building trust to enable moving towards true condition-based maintenance."– Louisa De Vries, asset innovation manager for rollingstock services, Downer Group

Keeping road traffic flowing smoothly

Another major transport vector is roads, and IoT projects here involve both the roadways and also the future generation of vehicles that will run on them.

ASX-listed toll road operator Transurban has sensors embedded in its roads and also uses toll point gantries to collect image and other data. Advanced analytics applied to this data ensures safe and efficient operation of the roads.

Data analytics lead analyst Michael Spence told last year’s Tableau Conference the fixed toll gantries were capable of collecting a lot of data about vehicles passing beneath them.

“As you drive under a toll point, we've got systems that take a photo of the front number plate, rear number plate, [and] the top of you,” Spence says.

“We measure you as a vehicle, we capture how fast you're going, and we classify you [as a] car, motorbike or truck.

“All of this stuff happens instantaneously, and we might have five lanes of road and you've got five vehicles going under a gantry at the same time. In peak hour traffic, there's thousands of cars flying through. There's lots of really cool information.”

The company augments this with data collected from sensors - essentially inductive loop detectors - that are installed at 500m intervals.

“The one problem with toll point information is that the toll points are miles and miles apart, so if we want to do traffic analysis, it's not enough information,” Spence says.

“We have loops - there's lots of different technologies - that have sensors under the road, and we [use them to] count cars and measure speed.

“If we supplement that with our toll point data, we get a good picture of what's happening on our roads.”

Transurban is aggregating all this data in Amazon Redshift and visualising it with software from Tableau.

Through its sensor data and analysis platform, it has been able to tackle problems such as traffic flow breakdown - recognising the point at which traffic stops flowing freely and becomes congested.

Three years ago, visualising this “was unimaginable,” Spence says. “This is billions and billions of rows of data that underpin this.”

However, the company is now able to determine the point where drivers will no longer be able to sustain the speed limit of the road. It can then make changes, such as stopping or slowing the volume of traffic entering the motorway at certain points, evening out the load.

“We don't want traffic to breakdown. When traffic breaks down, it's hard to recover again. We could never understand or work out that number without having this data and having a platform to visualise it.”

IDC associate market analyst Liam Landon notes there are other significant road-based sensing initiatives in Australia.

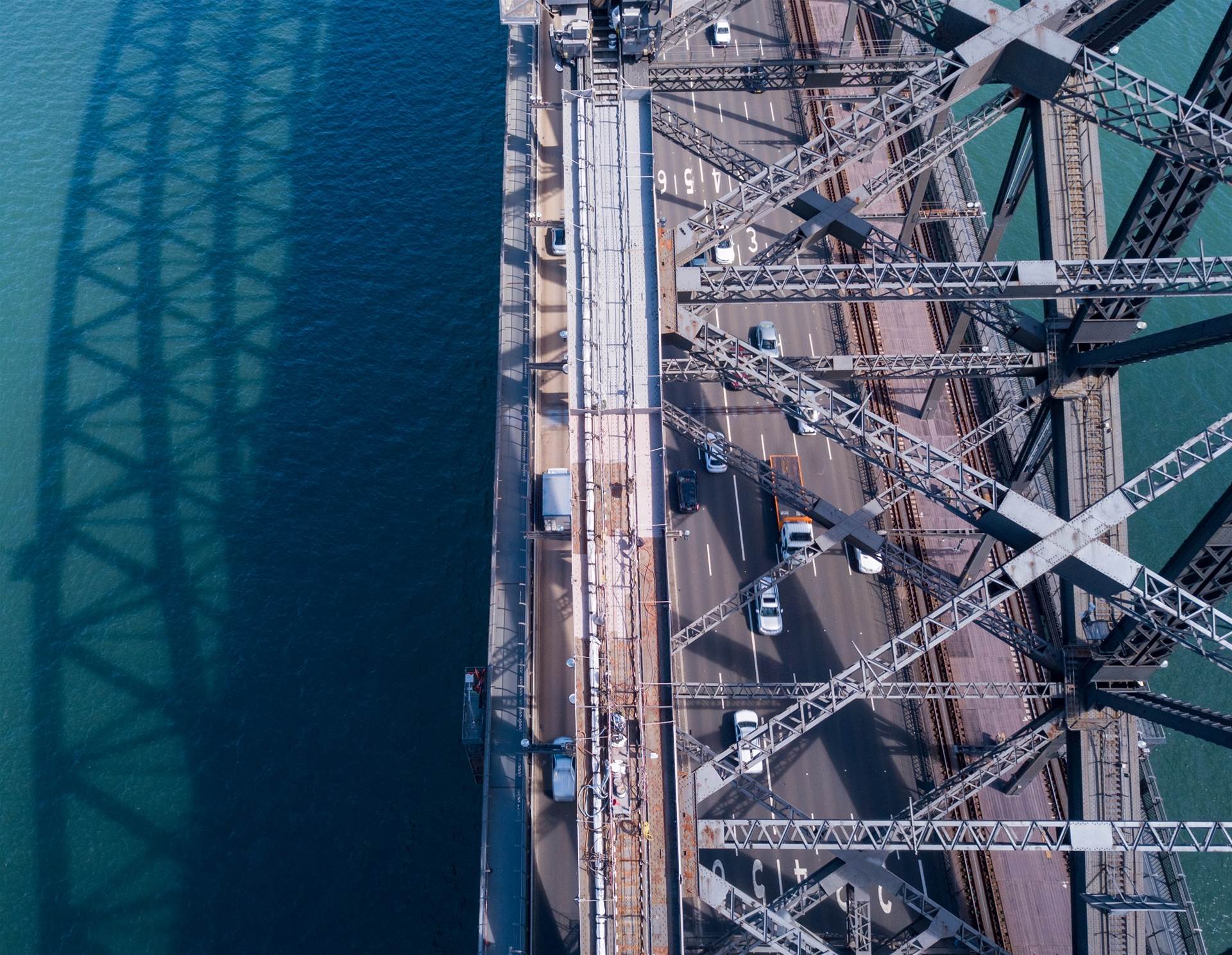

“Data61 (CSIRO's data sciences arm) has placed 2400 sensors on the Sydney Harbour bridge to monitor the bridge's 800 steel and concrete supports. The data from the sensors lets Data61 identify priority locations for proactive maintenance,” says Landon.

“[Additionally] Sydney's Coordinated Adaptive Traffic System (SCATS) is a connected network that coordinates traffic signals to optimise traffic flow throughout Sydney, which reduces delays on average by 20 percent and emissions by 7 percent.

“As our population grows and people migrate more into city living environments, managing critical infrastructure more effectively and efficiently becomes crucial for any developed society."

It’s not just roads that are being IoT-enabled, with future vehicles also set to become connected, too, as 5G networks become more widely available.

According to Gartner distinguished analyst Kristian Steenstrup, “connected cars provide the largest opportunity for 5G IoT in the long-term, which Gartner predicts will represent 53 percent of the overall 5G IoT endpoint opportunity by 2023.”

“This opportunity is driven by the automotive industry’s interest in and motivation to strengthen its offerings using digital technologies,” says Steenstrup.

“In addition, IoT for connected cars will require a mix of ultra-reliable low-latency communication (URLLC) and massive machine type communication (mMTC), depending on the use, to enable mobile vehicle-to-everything (C-V2X) communications to become a reliable and safe reality.

“Going forward, URLLC will be required to enable the remote piloting of autonomous vehicles.

“This opportunity, of course, will be dependent on automotive manufacturers incorporating 5G communications interfaces; telcos rolling out sufficient network coverage; and regulatory bodies legislating to allow 5G operations.”