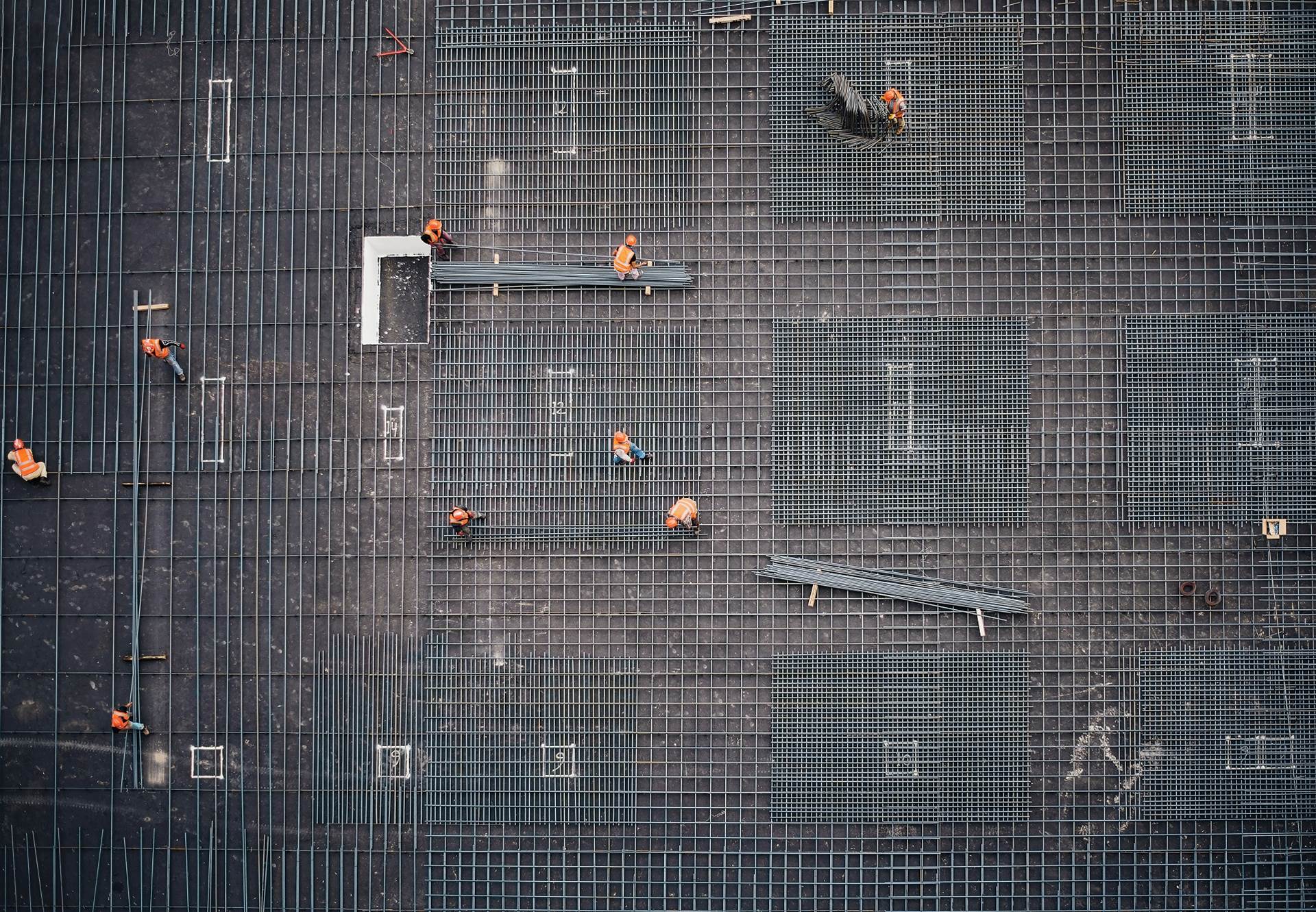

Before the COVID-19 crisis, Australia’s construction sector generated over $360 billion in revenue, and accounted for nine percent of Australia’s GDP, according to the Australian Industry and Skills Committee.

It is an industry that has long been on the cusp of change but that is now starting to make in-roads, with an increasing number of players, from Kennards Hire to Lendlease making a greater use of big building data and smart technologies.

“Like everyone who's in the property and construction sectors, there's a realisation that … our sector continues to see a downward trend in productivity - it costs us more to accomplish the same amount [as sectors like automotive and manufacturing],” Lendlease’s CEO of digital Bill Ruh tells an EY podcast earlier this year.

“We're [now] looking to accomplish what essentially these other industries have done with digital, which is what can help us really get that productivity, and bring down the cost, time and risk of … these great places that we build.”

Kennards Hire’s IoT evolution

When Kennards Hire started on its IoT journey - branded Easytrak - it saw an opportunity to track and manage some of the 120,000+ assets it rents to construction sites and other equipment users.

The range of assets Easytrak covers is vast, from large excavators to angle grinders and barricades.

Sensors on heavy earthmoving equipment such as excavators enable Kennards Hire to manage the location of equipment and determine if equipment is being used as agreed. Real-time utilisation data also determines when the equipment needs maintenance or servicing.

One year on, the company has substantially matured in its approach to IoT. It is no longer just instrumenting assets, but embedding IoT deeper into operational workflows.

This is improving and optimising the efficiency with which the Kennards Hire business runs.

“We're still connecting assets, but we're finding as we go through this process and look at the full end-to-end workflow that there are broader business requirements, and IoT is just part of that,” General Manager of Strategic Projects Craig Kesby tells IoTHub.com.au.

We’re understanding how equipment is used, but then what other data we can add in to enrich what we're getting back from the telemetry to actually make an improvement in a workflow or an operational task.

Kennards Hire’s IoT evolution

.

One of the ways that Kennards Hire has been able to embed IoT more deeply into its business processes and workflows is by embedding the team responsible directly into its frontline operations.

The entire team now works out of one of the company’s busiest hire locations in Artarmon on Sydney’s lower north shore, where they experience staff and customers challenges firsthand, and can more easily identify opportunities for improvement within existing hire processes.

“We're now part of an operating business as opposed to a separate unit [sitting] on the outside,” Kesby says.

“Co-locating the team in an operating environment so they can just bounce ideas off staff and customers, move equipment around and quickly iterate is a far more successful, Agile way to work, turn things around and make sure they’re useful straightaway.”

One of those creations from that is a new area search tool, which allows a branch to quickly identify hire vehicles that may have been involved in a traffic incident - something that previously involved ringing around different branches to track down the driver and vehicle involved.

“Often in a business like ours, we'll get somebody call and say, 'Hey, at 10 o'clock this morning on King Street in Newtown, one of your vehicles sideswiped my car. I didn't grab the rego, but this is what happened and I want to know who did it’,” says Kesby.

“Before, it was incredibly difficult to try and work out. But the team built a small tool to perform area searches.

You drag a circle on a map, put in the time range that you want, and it'll then give back to you in five or six seconds every asset that we've tracked that's been through that area during the time window that you chose.

“It gives you each of the assets and gives you the trip that it was on, so you can see exactly the time they were in there and plot those on the map. Straightaway you can find out which vehicles were in the area, see who hired them, and find their contact details to call them.

“It’s a small tool but it made a big operational difference, and it came from a direct conversation with people about how they work.”

On a broader scale, Easytrak is evolving beyond its IoT roots, so much so that it is reinventing itself as the internal home of real-time operational insight.

“We started as IoT and probably still think of ourselves as IoT, but a lot of the requests we have now from our own business are for integration into other systems to bring data together,” Kesby says.

“If you want to know what's happening with the business right now and what you should do right now in operations, that's where we come in. We’re an aggregation point for operational data.

The place we want to get to is a single pane of glass for the operation of the business in real-time. That involves a lot of data beyond telemetry: from our ERP, other systems and third party systems, which we then bring in to take care of servicing, transport and logistics. We run a lot of that through this system now.

Another unanticipated evolution for Easytrak is the outside interest in it from companies with similar fleet challenges - to the point where Kennards Hire is now commercialising Easytrak as a platform in its own right.

“We've got a couple of customers outside of Kennards Hire on the platform using it for subsets of what we use it for ourselves,” Kesby says.

“We’ve also had our first couple of discussions with partners who want to license the platform to integrate into the systems that do other parts of the work around building and construction, or refrigerated transport.”

Easytrack’s growth and evolution over the past year is particularly pleasing to Kesby, given the construction industry’s challenges with digital adoption.

“Building and construction is a pretty tough industry for digital to get traction, so we know if the industry is happy with what we’ve produced, we're onto a winner.”

Cognitive buildings

Smart technology and sensors are also increasingly being used to manage commercial buildings and high-rises.

Monash University is starting to experiment with cognitive office building systems it has been working on in partnership with Honeywell since the start of 2018.

At the time, the University announced an intention “to use big data to enable their buildings to intelligently and automatically alter the internal environment, transforming the way staff and students live, work and learn at the University.”

The program of work was also billed as a contributor to Monash University’s Net Zero initiative, under which the University aims to achieve net zero carbon emissions by 2030.

Faculty of IT Professor Tim Dwyer explains that the project began with an initial exploration of the technologies.

Research Fellow, Dr Arnaud Prouzeau, led a team of undergraduate students to collect data from one of our lecture theatres at the Monash Clayton campus. Over a period of a few months, they collected data on temperatures, energy use, wifi data to infer occupancy, etc.

They then developed techniques for visualising and analysing this data and were able to establish that some fairly straight-forward rule-based approaches to controlling HVAC [heating, ventilation and air conditioning] systems could lead to significant energy savings.

Following this initial work, the research went in two different directions.

One of those directions aims to develop “machine learning techniques to more intelligently and adaptively control the heating and cooling systems to achieve even greater energy savings without compromising occupant comfort,” according to Dwyer.

The other involves creating “immersive AR and VR techniques” to allow facilities managers to visualise building data in situ. “For example, a facilities manager might inspect a lecture theatre and, through their headset, see the historical temperature and energy use overlaid [on] the room, together with “x-ray” vision to see airflow in heating and cooling ducts through walls,” Dwyer says.

“As buildings and other complex systems become ‘smarter’ and driven interactively from live sensor data, it will become essential to have in situ visualisation tools to help users and occupants understand how they are operating.”

Until now, however, this has all been purely a research project, run using simulations as opposed to actual buildings, Dwyer explains.

This is now changing.

“We are [now] working with Monash Buildings and Properties to experiment with a limited deployment of the technologies - subject to obvious security and safety limitations,” Dwyer says.

Most existing building systems, such as HVAC and wi-fi access points, already collect data, though it may not be used or analysed further.

“Our research is about what transformation is possible when we take advantage of this available data intelligently,” says Dwyer.

“We are developing machine learning and immersive analytics techniques to support a cognitive building, which we are publishing in the relevant journals and conferences, and which we are sharing with engineers at Honeywell.

“It is our hope that the next phase of the project will lead to prototype deployments of the technology so we can actually trial and demonstrate the energy and performance improvements described earlier.”

Like many university campuses, Monash Clayton is effectively a small city that is home to buildings with a variety of uses, from residential (student accommodation) and retail (shops and restaurants around campus) to office space and teaching spaces, including large auditorium lecture theatres.

The University is also “rather unique”, Dwyer explains, in that multiple Monash campuses are under the control of a single facilities management staff.

“Therefore, we can easily access data and control systems across a large variety of sites,” he says.

“Honeywell sees this as a great testbed for such emerging technologies and monitors the results with great interest.”

Rise of the digital twin

.

A major emerging use case for sensor data and analytics in the property sector are digital twins, which are essentially exact virtual replicas of physical spaces.

Lendlease’s CEO for digital Bill Ruh sees digital twins as an area of “great promise”.

“We can use a digital twin in the [building] design phase,” Ruh tells a recent EY podcast.

“The ability to build a full fidelity building - down to the nuts, the bolts, all the major components that will go in - and then have that twin - the simulation, the physics, and the ability to model the building before you build it - would allow us to deal with any design deficiencies, onsite planning or supply chain deficiencies that usually show up in the construction phase because our current designs just aren't good enough,” he says.

A digital twin is also useful for the ongoing operation and management of the building.

“What's going to be interesting is when we can take the twin into the operations phase, meaning that one digital twin is used in planning, then design, into the construction phase, and then it comes along with the building for the operations,” Ruh says.

“I think that life cycle is going to turn into the golden era of property and construction where we're going to see we can take out 10-20-30 percent of cost.”

One of the keys to more widespread use of digital twins in all phases of construction and building management will be getting the cost down.

“Where it used to be a few million dollars to do a digital twin, we're really in that US$250,000 [ballpark] to build a digital twin for a high-rise,” explains Ruh.

“To make this go mainstream in a big way, [there has] to be more automation of the digital twin, and we're working on that so that the actual design itself is not so much handcrafted, but is automated.

“I think we can see these digital twins down at US$50,000, which makes them virtually free in many, many cases for the building sector.

“That's when things get exciting, and I think we're three years away from that. And then in five years, I think it'll be very natural that automated design and digital twins are being used on a daily basis.

“And then 10 years from now, it's just going to feel like we've always been doing it.”

To get there, several outstanding challenges will need to be resolved.

According to Ruh, the technology behind digital twins remains “hard” and requires significant domain knowledge.

The twins themselves are also computationally intensive.

I think we're going to have to look to someplace like the gaming industry to make this useful in the cloud and make it easy to distribute the output.

The bigger challenge is to prepare the construction sector for what might happen if digital twins become part of the standard operating model.

Ways of thinking will change. Jobs will change. People in the sector need to be prepared for that.

‘I think those challenges are very, very real,” says Ruh.